Product

Integrated Manufacturing of Medical-Grade Tubes and Precision Processing We provide integrated production capabilities combining medical-grade tubing with precision processing.

Through advanced quality management across the entire manufacturing process,

we meet the stringent accuracy standards of the medical industry down to the finest details.

From prototype development to mass production, we can supply at any scale.

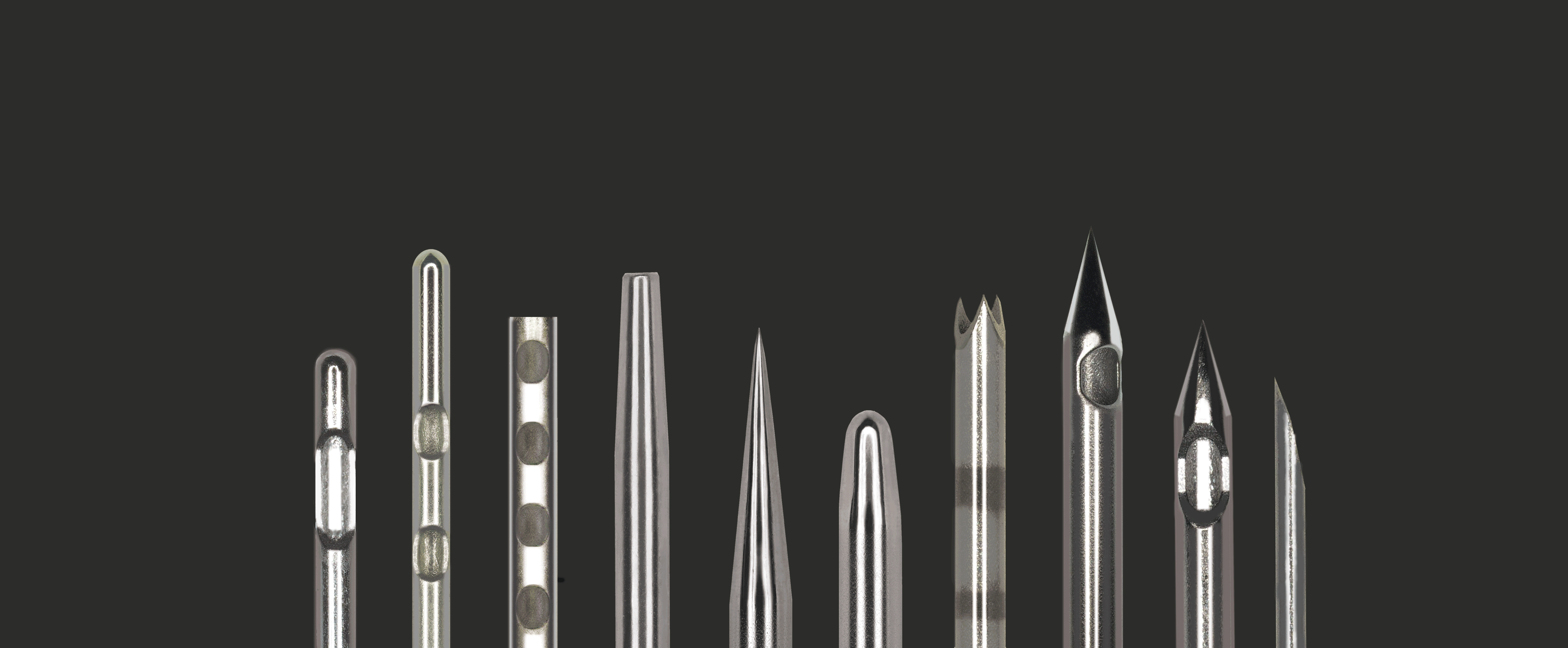

Cannula

Franseen

A tip shape with three cutting surfaces that allows tissue penetration in a tubular form.

Main applications: biopsy needles, etc.

Blade length and angle can be customized to meet your requirements.

Lancet

The most basic and widely adopted needle tip shape for injection needles.

Main applications: general needles (subcutaneous injection), blood collection needles, etc.

Blade length and angle can be customized to meet your requirements.

Back Cut

A needle tip shape featuring a small additional blade surface on the reverse side, also known as “back bevel.”

Main applications: indwelling needles, biopsy needles, etc.

Blade length and angle can be customized to meet your requirements.

Other Variations

We also offer:

・Semi-lancet

・Multi-facet needle

・Short needles (L ~ 10mm)

All can be processed with customized blade lengths and angles.

Processing

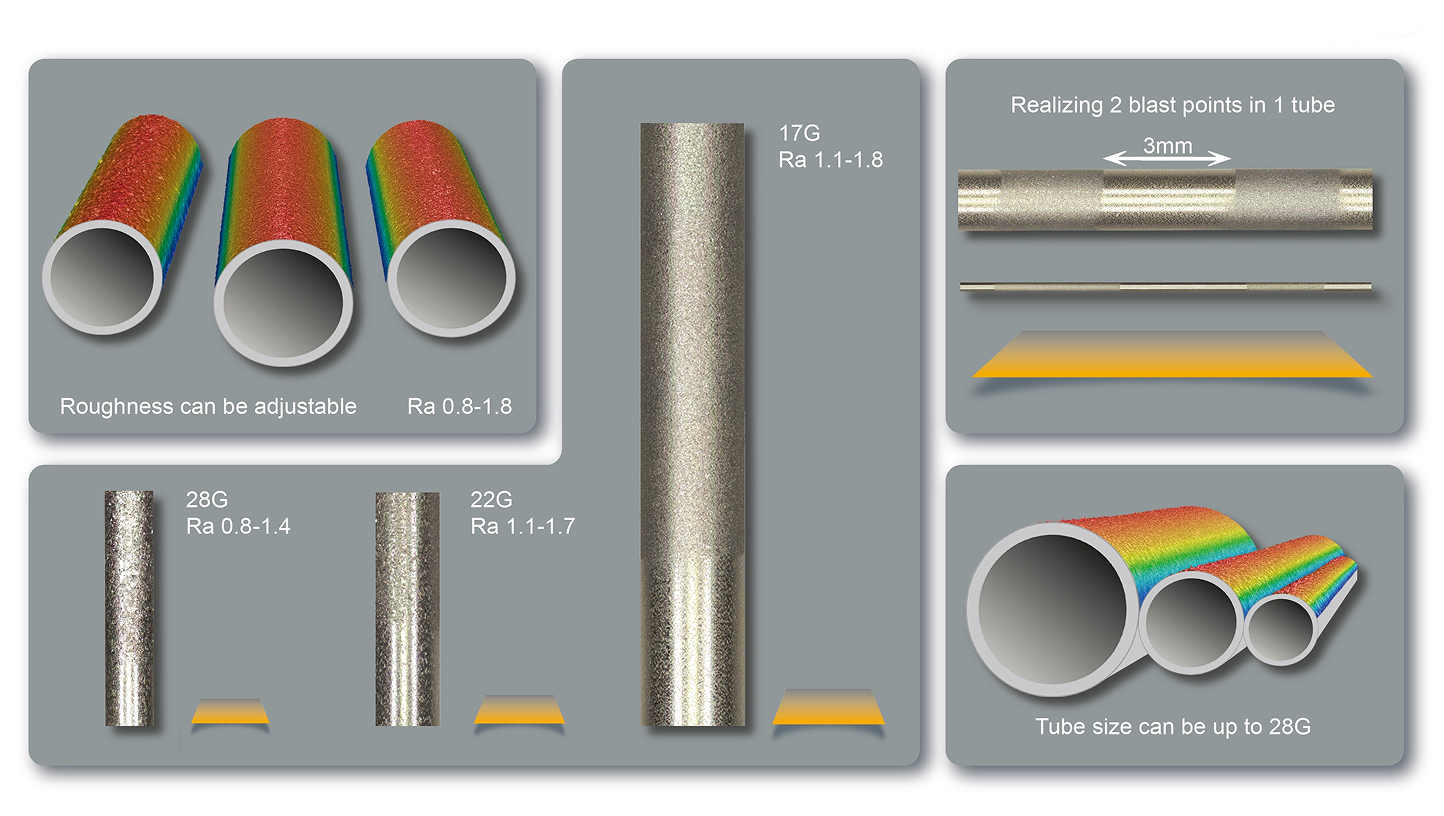

Blasting

A surface treatment in which particulate abrasives are blasted onto the product with compressed air for surface removal and polishing, achieving the desired surface roughness.

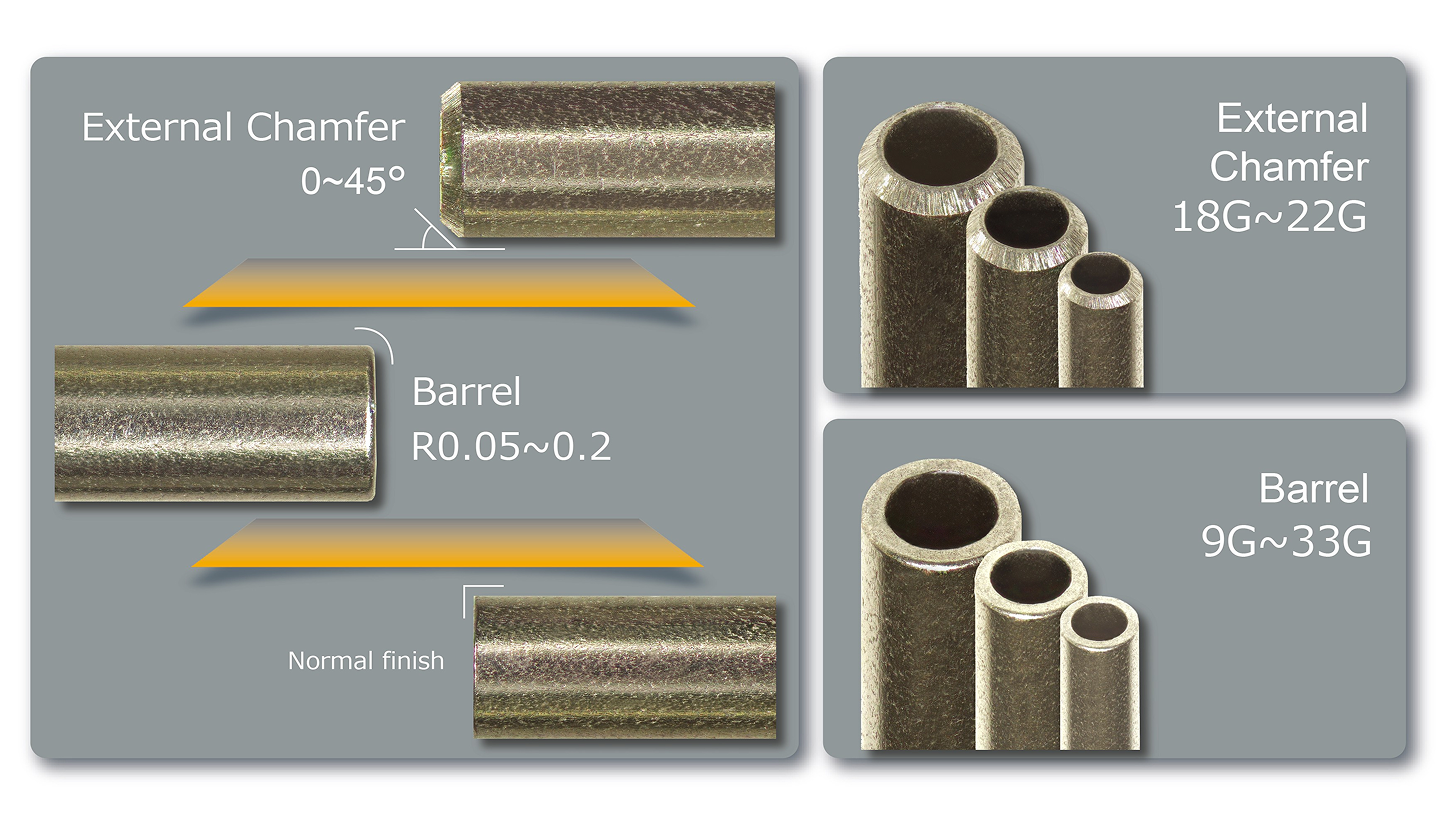

Edge Treatment

Products are placed in a barrel with abrasives, water, and compound at a specified ratio. By rotating or vibrating the barrel, relative friction removes burrs, creates rounding (R-edges), and improves surface quality.

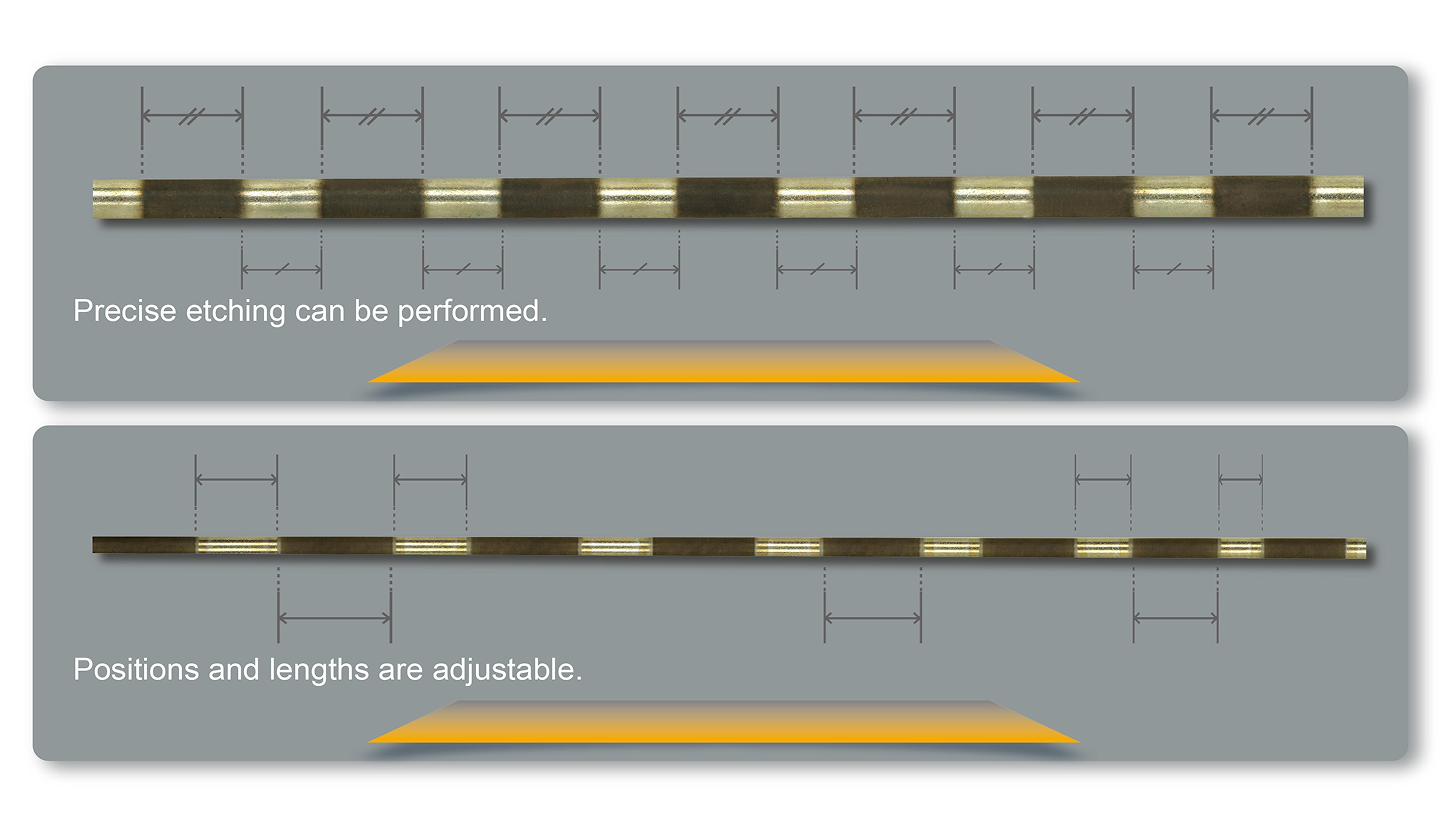

Etching

Using an electrolytic solution (chemical solution) and applying low voltage to conductive metals, chemical reactions are induced on the metal surface for controlled dissolution processing.

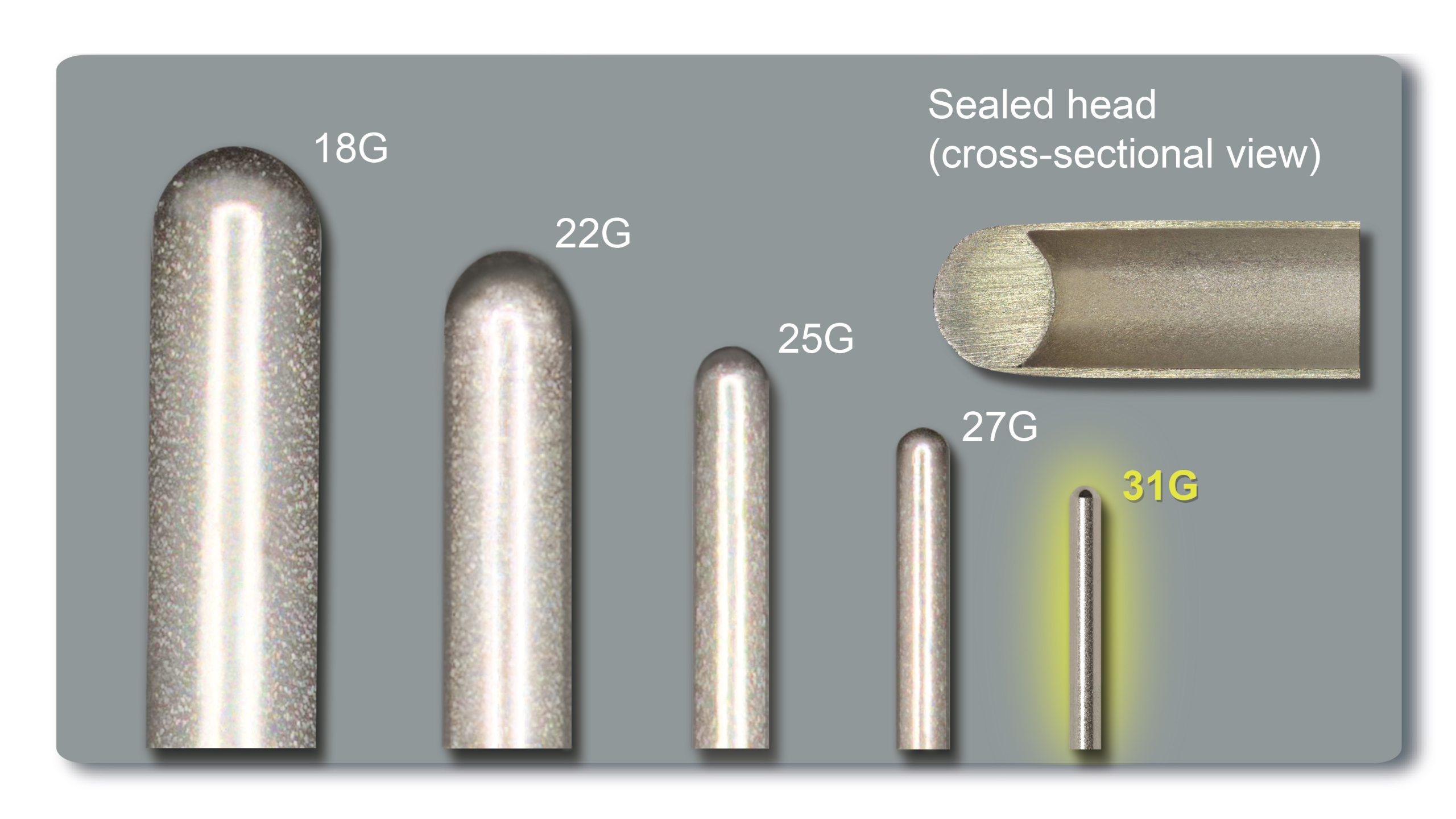

Tip Welding

Sealing the tip of ultra-fine pipes (φ0.25 mm and above) by welding.

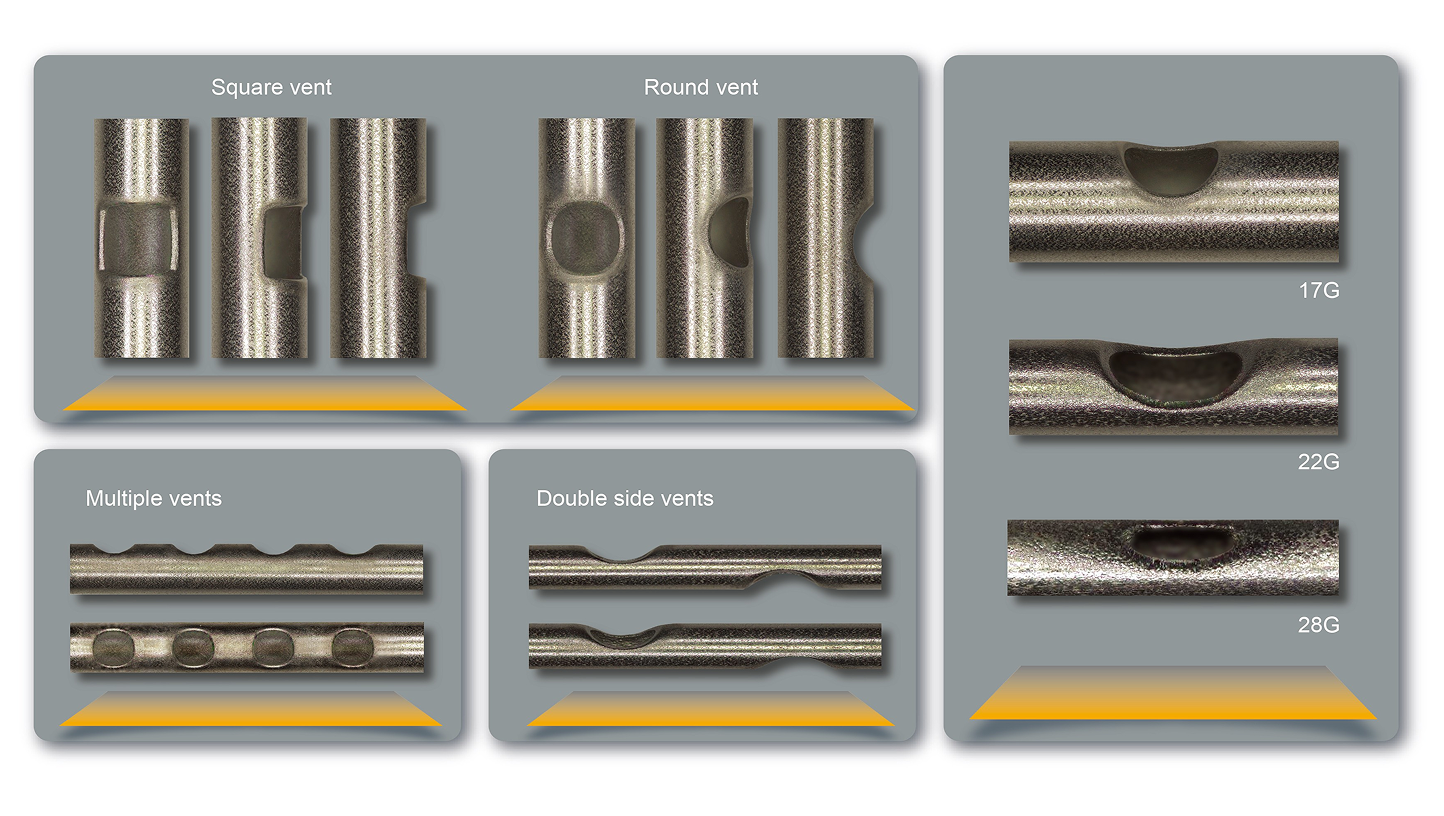

Electrolytic Grinding Side Vent

Drilling side holes of arbitrary size and number at the tube tip. Using an electrolytic grinding machine, we achieve burr-free, high-precision holes.

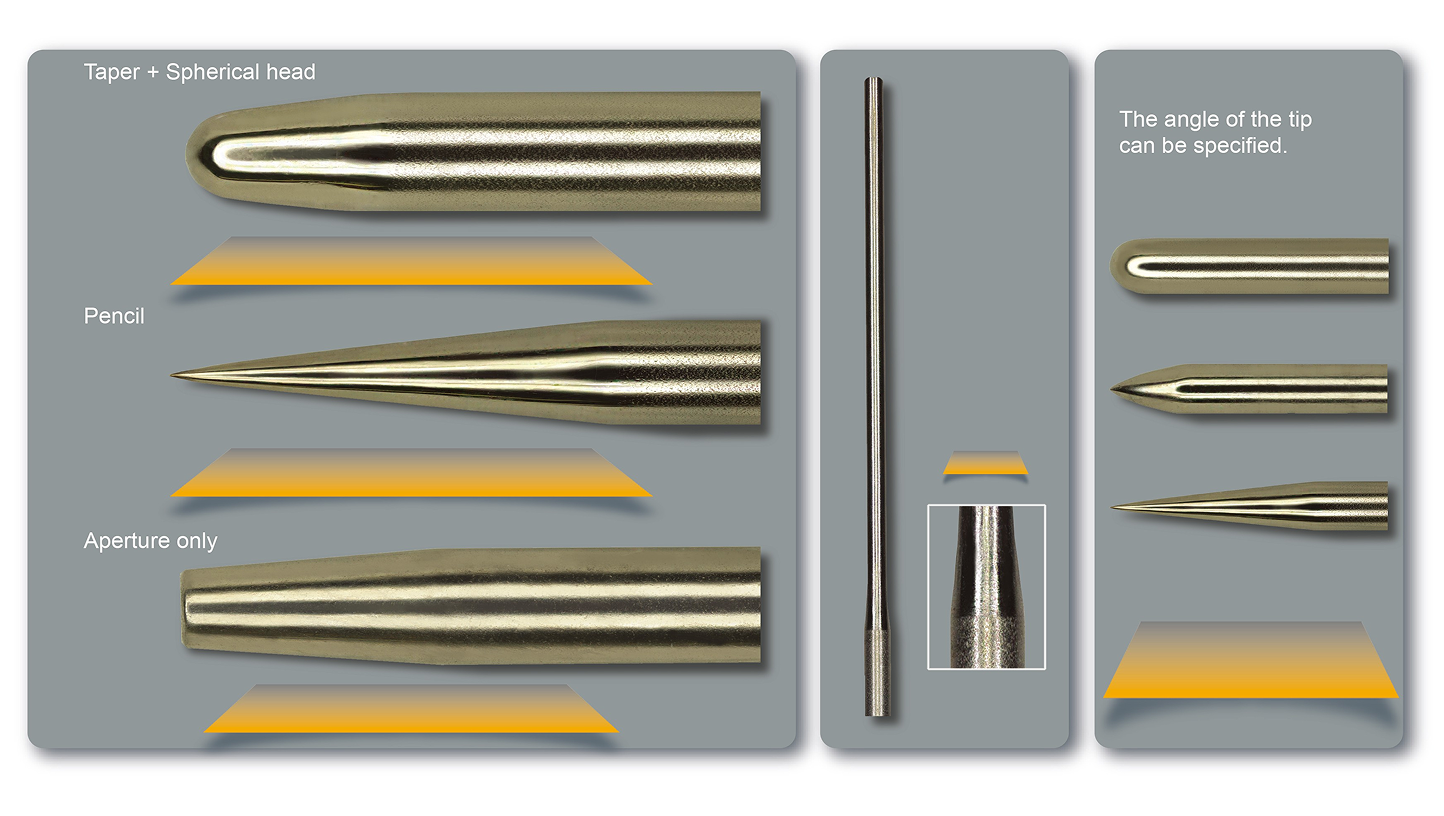

Swaging

By rotating a die and striking the pipe, the outer diameter is gradually reduced while elongating the pipe. The tip can be shaped into various forms, such as spherical or pen-like points, according to customer requirements.

Composite

Multiple processing methods can be combined on a single tube. Examples: ・Tip sealing + side hole drilling ・Swaging + side hole drilling We accommodate a wide range of processing combinations with flexibility.